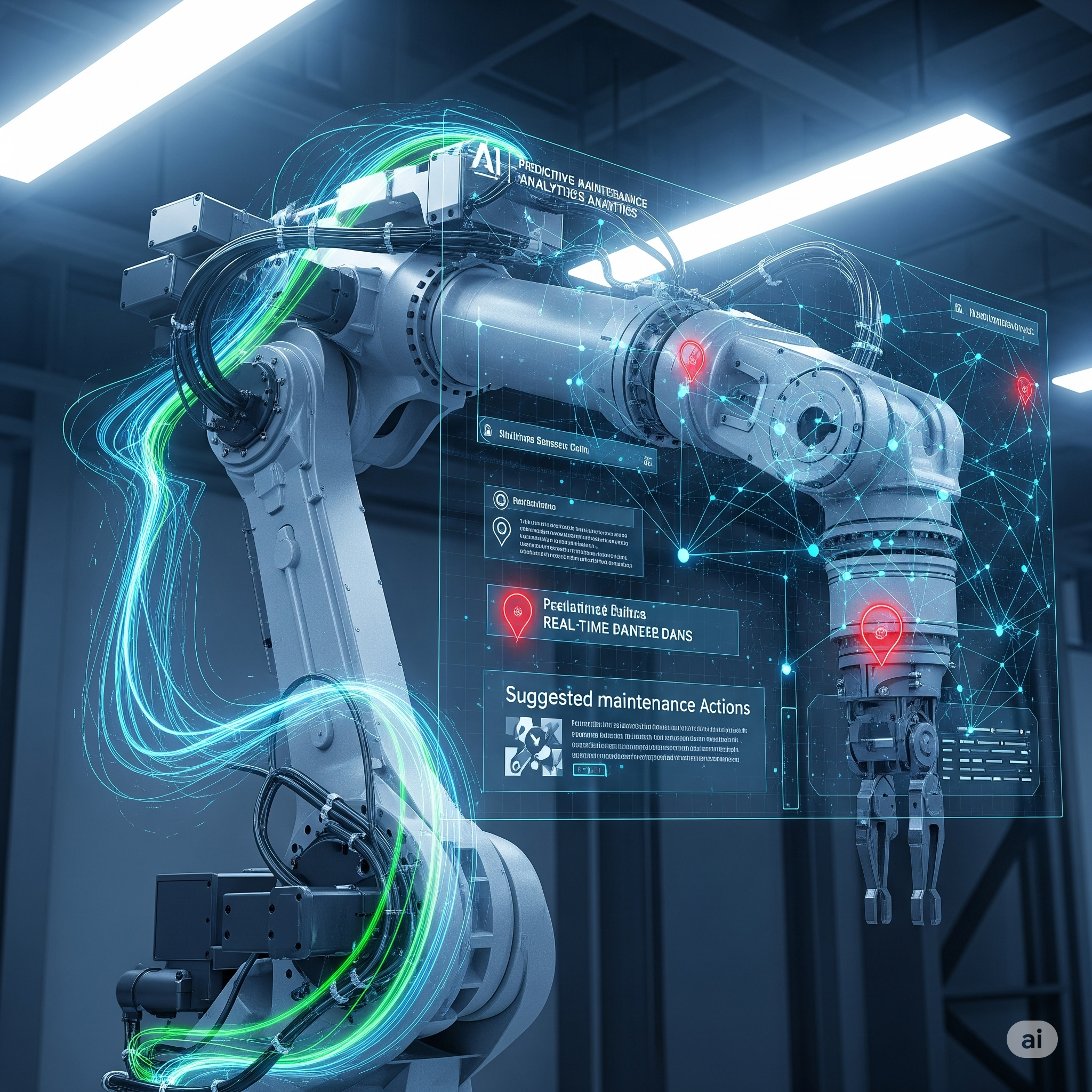

In the high-stakes worlds of engineering and manufacturing, unplanned equipment downtime can trigger a cascade of costly consequences. Production halts, missed deadlines, wasted materials, and reputational damage are just a few of the potential repercussions. For decades, maintenance strategies have largely revolved around reactive repairs (fixing breakdowns as they occur) or preventative maintenance (scheduled maintenance at fixed intervals, regardless of actual need). While preventative measures are a step forward, they often lead to unnecessary maintenance on healthy equipment or fail to catch impending failures between scheduled checks. This is where a revolutionary technological shift is taking center stage: AI predictive maintenance.

The integration of AI predictive maintenance is transforming how industries approach equipment upkeep, moving from a reactive or time-based model to a proactive, data-driven strategy. By leveraging the power of artificial intelligence and machine learning, AI predictive maintenance systems can analyze vast amounts of sensor data, operational logs, and maintenance history to predict when equipment is likely to fail. This foresight allows engineers and manufacturers to schedule maintenance only when and where it’s truly needed, minimizing downtime, optimizing resource allocation, extending equipment lifespan, and ultimately boosting overall operational efficiency. This article will delve into the critical role of AI predictive maintenance in modern engineering and manufacturing, exploring its mechanisms, showcasing real-world successes, highlighting key enabling technologies, and providing a guide for adoption.

The Foundation of AI Predictive Maintenance: Data and Insight

At its core, AI predictive maintenance hinges on the collection and analysis of data from industrial assets. This data can come from a variety of sensors embedded in machinery, including those measuring temperature, vibration, pressure, acoustic emissions, and electrical current. These sensors, often part of the Industrial Internet of Things (IIoT), continuously stream data to a central platform. The true power of AI predictive maintenance is unleashed when this raw data is fed into sophisticated machine learning algorithms.

These algorithms are trained on historical data, including past equipment failures, maintenance records, and operational parameters. By identifying patterns and anomalies within this data, the AI can learn to recognize the subtle indicators that precede equipment failure. Unlike traditional threshold-based monitoring systems that simply trigger alerts when a predefined limit is exceeded, AI predictive maintenance can detect more complex and nuanced relationships in the data, providing early warnings of potential issues that might otherwise go unnoticed until a catastrophic breakdown occurs. This capability to “see the invisible” is what makes AI predictive maintenance such a game-changer for engineering and manufacturing operations.

How AI Algorithms Power Predictive Maintenance

The effectiveness of AI predictive maintenance relies on various machine learning techniques working in concert. These algorithms analyze historical and real-time data to generate insights and predictions about equipment health.

Supervised Learning for Failure Prediction

In supervised learning, AI models are trained on labeled data, where instances of normal operation are distinguished from instances of failure. The algorithm learns to identify the patterns and conditions that are strongly correlated with equipment breakdown. Once trained, these models can analyze real-time sensor data to predict the probability of failure within a specific timeframe, allowing maintenance teams to intervene proactively.

Unsupervised Learning for Anomaly Detection

Unsupervised learning techniques are particularly useful for detecting unusual patterns or anomalies in equipment data without prior knowledge of specific failure modes. These algorithms can identify deviations from normal operating conditions that might indicate an emerging issue, even if it doesn’t match any previously seen failure patterns. This is crucial for catching unexpected or novel types of equipment malfunctions.

Time Series Analysis for Trend Forecasting

Many sensor readings in industrial equipment form time series data (data points collected sequentially over time). AI predictive maintenance utilizes time series analysis techniques to identify trends and predict future values based on historical patterns. For example, an AI might detect a gradual increase in the vibration levels of a bearing over time, indicating an impending failure even if the current vibration levels are still within acceptable limits.

Real-World Impact: Case Studies in AI Predictive Maintenance

The adoption of AI predictive maintenance is delivering significant benefits to engineering and manufacturing companies worldwide. These real-world examples highlight the tangible impact of this technology on operational efficiency, cost reduction, and overall productivity.

Case Study 1: “Global Manufacturing Corp” and AI-Driven Downtime Reduction

“Global Manufacturing Corp,” a large automotive parts manufacturer, struggled with frequent unplanned downtime across its assembly lines. These disruptions led to significant production losses and missed delivery targets. By implementing an AI predictive maintenance system that monitored critical equipment using vibration, temperature, and acoustic sensors, they were able to drastically reduce these issues.

The AI algorithms analyzed the sensor data in real-time and provided early warnings of potential failures in key machinery, such as robotic welders and automated conveyors. This allowed their maintenance teams to schedule targeted interventions during planned downtime, addressing the issues before they caused a breakdown. Within the first year of implementation, “Global Manufacturing Corp” reported a 20% reduction in unplanned downtime, a 15% decrease in maintenance costs, and a significant improvement in overall equipment effectiveness (OEE).

Case Study 2: “Precision Engineering Ltd.” and Proactive Maintenance on Critical Machinery

“Precision Engineering Ltd.,” a company specializing in the production of high-precision components for the aerospace industry, relies heavily on the continuous operation of its sophisticated CNC machines. Unplanned downtime of these expensive assets could lead to significant delays and financial losses. They implemented an AI predictive maintenance solution that integrated data from the machines’ control systems, as well as dedicated vibration and temperature sensors.

The manufacturing AI solutions deployed provided real-time insights into the health of critical components, such as spindles and bearings. The AI algorithms learned the unique operational “signatures” of each machine and could detect even subtle deviations that indicated an impending problem. This proactive approach allowed “Precision Engineering” to schedule maintenance interventions before catastrophic failures occurred, preventing costly repairs and ensuring the continuous operation of their critical machinery. According to industry reports, such as those from HubSpot on AI in operations, proactive maintenance is a key driver of efficiency in modern manufacturing.

Essential Tools and Technologies for AI Predictive Maintenance

Implementing AI predictive maintenance requires a combination of hardware and software solutions. Here are some key tools and technologies that enable this transformative approach:

- IIoT Sensors and Data Acquisition Systems: These devices collect real-time data from industrial equipment and transmit it to a central platform for analysis. Companies like Bosch, Siemens, and Honeywell offer a wide range of industrial sensors.

- Cloud-Based AI and Machine Learning Platforms: Platforms such as AWS Machine Learning, Google Cloud AI Platform, and Microsoft Azure Machine Learning provide the infrastructure and tools needed to build, train, and deploy AI models for predictive maintenance.

- Data Historians and Industrial Data Platforms: These systems are designed to store and manage the large volumes of time-series data generated by industrial equipment. Examples include OSIsoft PI System and Aveva Historian.

- Predictive Analytics Software: Specialized software solutions, such as those offered by companies like Uptake, GE Digital, and SAS, provide pre-built AI models and tools specifically designed for AI predictive maintenance applications.

- Data Visualization Tools: Platforms like Tableau and Power BI are crucial for visualizing the insights generated by AI models, making it easier for maintenance teams to understand equipment health and prioritize actions.

Implementing AI Predictive Maintenance: A Step-by-Step Approach

Adopting AI predictive maintenance can be a significant undertaking, but a structured approach can help ensure a successful implementation.

- Identify Critical Assets: Begin by identifying the most critical equipment in your operations – the assets whose failure would have the most significant impact on production and costs. Focus your initial efforts on these high-value assets.

- Assess Data Availability and Quality: Evaluate the availability and quality of data from your critical assets. Determine what sensors are currently in place and whether additional sensors are needed. Ensure that the data is accurate, reliable, and consistently collected.

- Choose the Right AI Platform and Tools: Select an AI platform and predictive analytics software that aligns with your technical capabilities, budget, and specific needs. Consider whether you want to build custom models or leverage pre-built solutions.

- Develop and Train AI Models: Work with data scientists or leverage the tools provided by your chosen platform to develop and train AI models using your historical and real-time equipment data. This process may require experimentation and fine-tuning to achieve the desired level of accuracy.

- Integrate with Existing Maintenance Systems: Integrate your AI predictive maintenance system with your existing maintenance management software (CMMS) to streamline workflows and ensure that maintenance actions triggered by AI insights are properly scheduled and tracked.

- Monitor Performance and Iterate: Continuously monitor the performance of your AI models and make adjustments as needed. The effectiveness of AI predictive maintenance improves over time as more data becomes available and the models are further refined.

The Future of AI in Industrial Maintenance: Towards Autonomous Operations

The field of AI predictive maintenance is constantly evolving, with the future promising even more sophisticated capabilities. We can anticipate a greater integration of AI with other advanced technologies, such as digital twins, augmented reality (AR), and robotics, leading to more autonomous and efficient maintenance operations. Imagine AI systems not only predicting a failure but also autonomously dispatching a robot equipped with AR guidance to perform the necessary repairs.

Furthermore, the increasing availability of edge computing will enable real-time analysis of sensor data directly at the machine level, reducing latency and enabling faster decision-making. The ultimate goal is to create intelligent and self-aware industrial assets that can proactively manage their own health, minimizing human intervention and maximizing uptime.

Conclusion: Embracing the Power of Prediction in Engineering and Manufacturing

In the competitive landscapes of engineering and manufacturing, the ability to anticipate and prevent equipment failures is no longer a luxury – it’s a strategic imperative. AI predictive maintenance offers a powerful solution, enabling businesses to move beyond reactive and preventative approaches to a proactive, data-driven model of asset management. By leveraging the power of artificial intelligence and machine learning, companies can significantly reduce downtime, lower maintenance costs, extend equipment lifespan, and ultimately achieve greater operational efficiency and profitability.

The journey towards AI predictive maintenance starts with understanding the potential of data and embracing the transformative capabilities of artificial intelligence. By taking a strategic and phased approach to implementation, engineering and manufacturing organizations can unlock the immense value of prediction and build a future where unplanned downtime becomes a rarity. The time to embrace the intelligence of AI predictive maintenance is now, and the rewards for those who do will be significant.